abstract

Membrane-controlled slow-release preparation is a common release mechanism, coating process is the most important process content of the preparation, coating by prescription and process, environmental factors, in order to deeply understand the prescription process and the environment on the final product, need to combine past experience and single factor experiment evaluation. This paper is a brief overview of the aging process of membrane-controlled sustained-release preparations.

Release investigation is an important investigation of the stability stage of membrane-controlled sustained-release preparation, and it is also one of the key quality attributes of this preparation. Compared with regular release preparations, membrane-controlled sustained-release preparations are more prone to release-related problems in the stability study stage. The main factors causing such problems include prescription composition and parameter control in the coating process, and the aging process is one of the important parameters. The change of release degree in the stability stage should be analyzed based on the characteristics of the preparation. In short, the structure determines the nature, and any change in appearance must come from the change in the internal structure of the preparation. As the core element of membrane release control, it is very necessary to understand the formation process and structure of the membrane.

1. Formation of a slow-release membrane layer

Solution coating system (organic solvent system) and water dispersion coating system are two common coating systems of slow and controlled release coating, but their film forming mechanism is significantly different.

For the solution coating system, the coating system mainly desolvates the polymer molecular chain, and then arranges the membrane; for the film forming system, the coating system is formed in water with solid or semi-solid spherical particles of 0.01 μ m-1 μ m. The film forming process is mainly composed of three stages:

First: the coating liquid is attached to and deposited on the substrate surface through atomization;

Second: water from the surface of the evaporation of polymer particles between the accumulation becomes close;

Third, with the dynamic operation of substrate friction and the melting of external temperature, adjacent polymer molecules cross diffusion to form a continuous coat.

2. The importance of coat coat aging

Broadly speaking, the whole process of film formation of sustained-release materials can be regarded as aging, that is, the process of polymer solution or particles aggregation into film after heat treatment. In the actual research and development process, we mainly regard the heat treatment process after the coating injection operation as aging, and aging is usually referred to as static aging in the oven. In order to reduce the transfer of clothing from coating pot to oven, some aging processes usually continue to continue with the rotation of the coating pot, often called dynamic aging, and different aging conditions are required by different coating systems.

For organic solvent coating system (solution type) because its solvent easy evaporation from the substrate surface between the crosslinking polymerization film chain in the process of spray coating can continue into film, so in the coating end point for weak heat treatment (generally in 40-50℃ dry 30-60min) and static aging and dynamic aging no significant difference;

For water dispersion whether intestinal or slow release must undergo aging process to form a complete coating, water dispersion system water evaporation need energy is relatively high so the coating material need to coating at higher material temperature, and because the moisture dispersion particles between strong exclusion so need certain driving force in the coating process between makes the particles can gather together and form a film.

Dynamic aging process by evaporation makes capillary pressure between particles and form dense film, such as no dynamic aging treatment cannot form dense and continuous membrane and may exist plasticizer crystal behavior and products in the long-term stability stage is susceptible to the influence of the external environment and the release of OOT phenomenon.

3. Judgment of the aging end point

Aging end point confirmation and the stability of the film has a direct relationship, so for the understanding of membrane structure change is particularly important, preparation developers in this respect usually adopts the beginning of thinking, directly to aging may affect the release of aging as an index of aging evaluation, with temperature, humidity, time for 3 d comprehensive investigation, confirm can obtain stable release trend of aging design space.

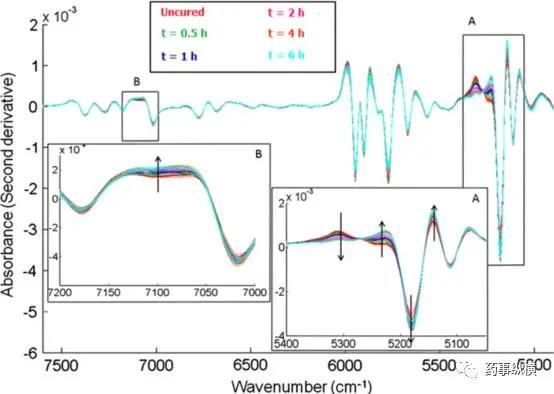

With the understanding of aging process, there are many mature analytical techniques that are also suitable for the aging evaluation of sustained-release film, including NIR, Raman, XuCT and other technologies can achieve more sensitive, direct and visual evaluation results in aging research. NIR technology has high sensitivity in moisture detection, it can be used for the aging research of moisture dispersion coating system; Raman technology can quickly determine whether the aging process will lead to the change of the chemical properties of the coating and the aging process; SuCT technology is mainly used to analyze the change process of the physical structure of the internal membrane material in the aging process and then intuitively analyze the change process of the coating membrane in the aging process.

In terms of laboratory coating research using dissolution method to electron microscope auxiliary detection can complete most of the aging optimization work, for the problems of complicated envelope release need to rely on the more intuitive analysis of the membrane structure of the membrane structure, and determine the aging conditions.

epilogue:

The research of aging process in the process is often insufficient, on the one hand, because the evaluation method is relatively single, on the other hand, or because the attention needs to be strengthened. The aging study of slow-release coating is just like the influencing factors of regular-release preparation. The more sufficient the study, the more conducive to the control of product quality. The author is well aware that the content and degree of aging research are related to the composition of the coating film and the composition of the solvent system, so it is difficult to summarize by single experience or data. There must be some shortcomings in the paper, and we hope that practitioners can communicate more and improve together.